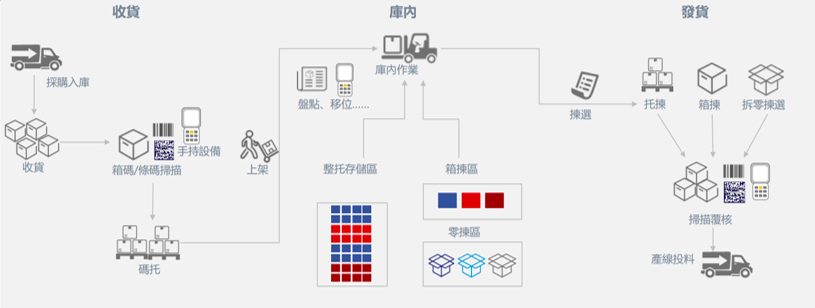

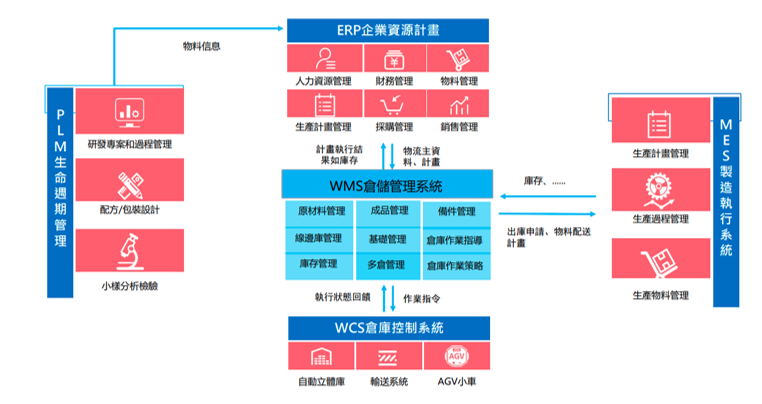

WMS(Warehouse Management System) is the implementation of microscopic-scaled of logistics automation. With the help of WMS(Warehouse Management System),the logistics will be traced and controlled electronically from material picking to delivery. WMS will receive all transit plans and let WCS calculate the optimal method of picking and transit path so that the efficiency and accuracy rate of inventory would increase.

Business Logic Regularization

Logistic process such as loading, unloading, picking, packing can be complicated and various in a logistic system. With business logic regularization, the engineer can set up corresponding operation algorithm for different material. The technician don’t need to set up the operation rules on by one so that the efficiency of logistic can be improved.

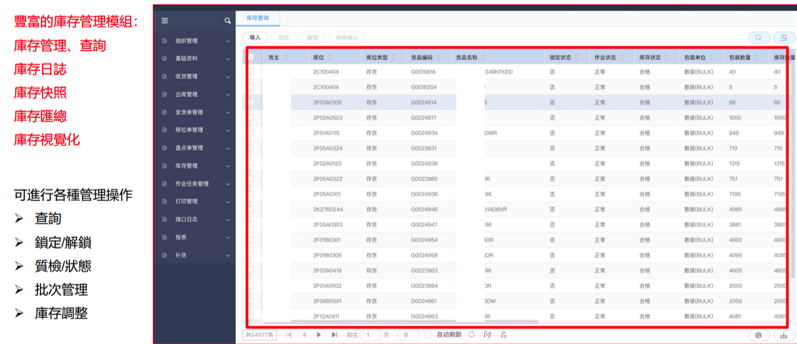

Inventory Management & Stocktaking

During loading, unloading, scrapping and stocktaking, WMS will report the inventory immediately so that the worker can monitor the logistics and understand the accuracy rate of inventory.

Warning Management

WMS provides warning management system, which can set up the expiry date and warning level of inventory. As a result, WMS can prevent inventory from expiry and shortage.

Loading Dock Reservation

WMS provides Loading Dock Reservation System which integrates ASN and the loading order from ERP. The supplier can reserve an appropriate time on Reservation System when sending an ASN message so that the efficiency of loading can be optimal.

Paperless

With RFID(Radio Frequency Identification)and bar code, all logistic process can be executed without paper. Workers can acquire corresponding information from RFID and bar code with mobile device, and thus WMS records information of inventory instantly.