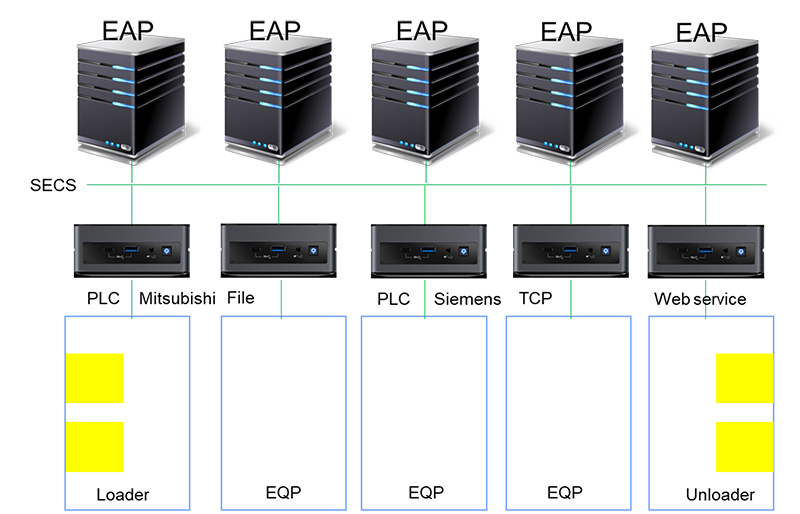

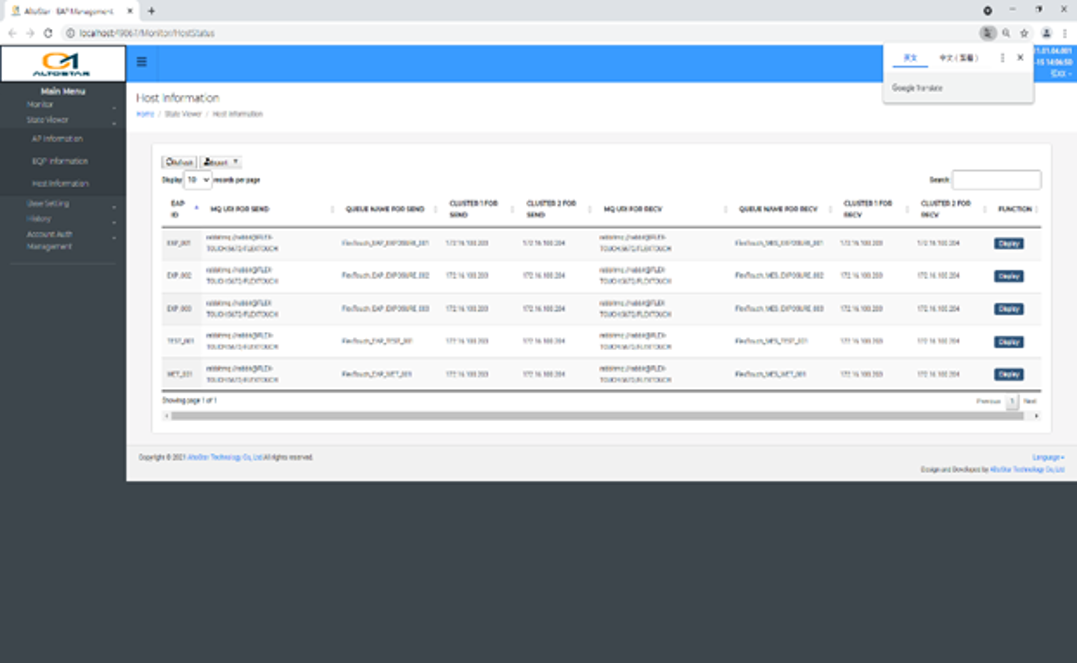

EAP(Equipment Automation Program) is the basis of automation of manufacturing. EAP can automatically control the equipment directly and receive engineering data from different machine. Thus, monitoring and analysis of manufacturing will be easier by EAP.

- EAP supports SECS/GEM protocol which semiconductor industry adopts.

- EAP receives all information of equipment and measurement data from ECM.

| EAP | Inline EAP | BC | |

|---|---|---|---|

| 設計手法 | 單一設備資料採集 | 整線整合式規劃 | 整線整合式規劃 |

| 通訊方式 | SECS/GEM | SECS/GEM | CCLink-IE |

| 通訊連結 | 1:N | 1:N | 1:N |

| 用戶界面 | 無 | 有 | 有 |

| 線體看板 | 無 | Inline 整合式畫面 | Inline 整合式畫面 |

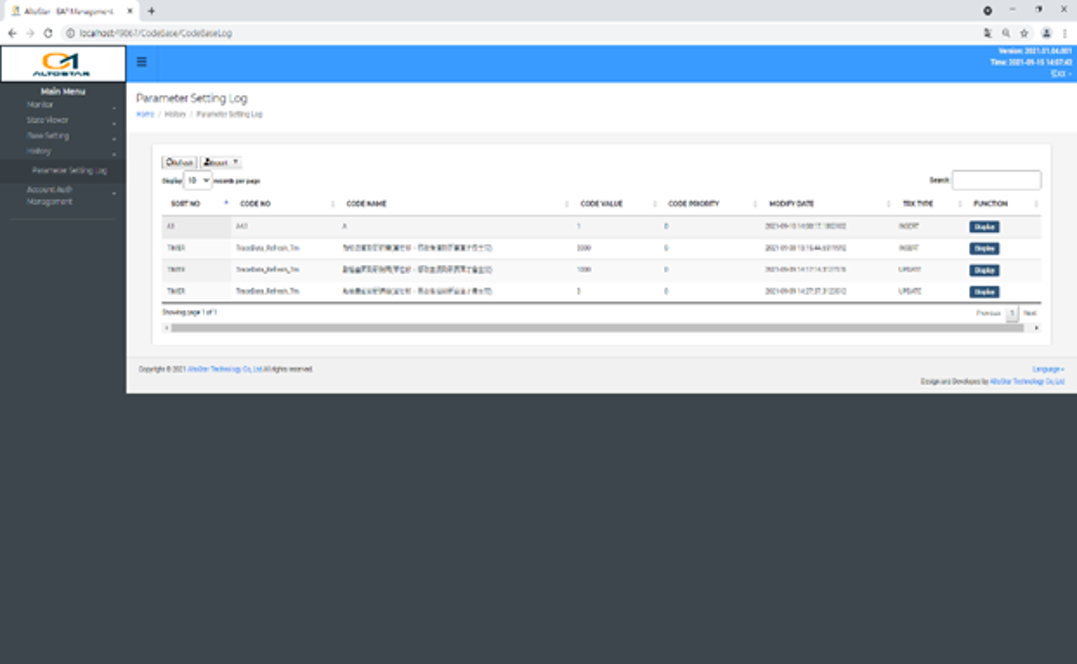

| 履歷查詢功能 | 無 | 有 | 有 |

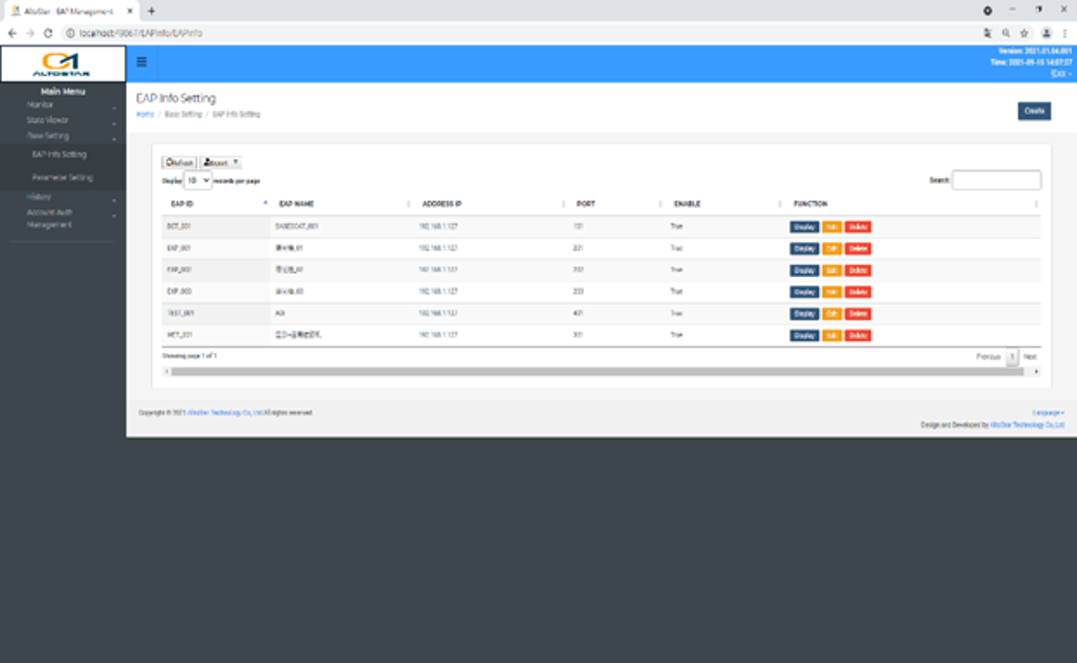

| 設定方式 | 文字檔 | 視窗界面 | 視窗界面 |