「Smart manufacturing (SM) is a technology-driven approach that utilizes Internet-connected machinery to monitor the production process. The goal of SM is to identify opportunities for automating operations and use data analytics to improve manufacturing performance.」──Ed Burns

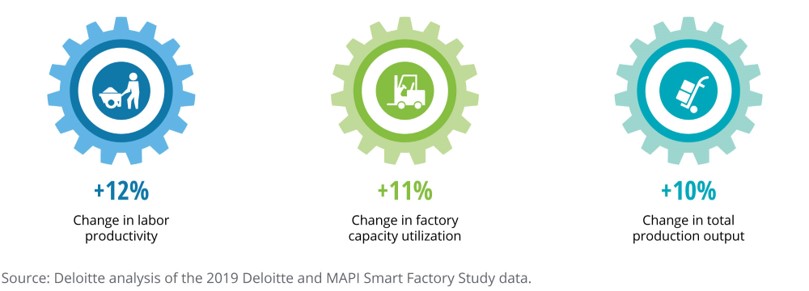

Improvement of labor productivity, factory capacity utilization and production output

The report form Deloitte in 2019 indicates that companies adopting smart factories increase the labor productivity, factory capacity utilization and production output by 12%, 11% and 10% in three years respectively. Moreover, the labor productivity of these companies will increase 2%-12% by 2022. As a result, smart manufacturing will be the ace in the hole in the changing market of manufacturing.