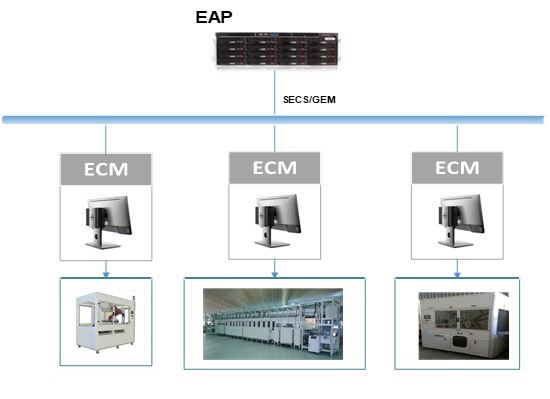

The power of ECM(Equipment Collection Mate) is that ECM support various communication protocol and upload the equipment data immediately, which achieve high accessibility of data. As a result, the process R&D would be faster, and the engineer can monitor all equipment on one platform such as EAP.

ECM supports various PLC such as Omron, Siemens, Mitsubishi in order to collect equipment data and measurement data.

ECM is widely applied for PCB industry.