BCS(Block Control System) authentically integrates the inline equipment. BCS integrate the state of inline equipment and WIP so that the equipment would produce efficiently and achieve the goal of balanced production rate.

BCS adopts CC-Link IE of Mitsubishi PLC in order to monitor the WIP data, equipment data and measurement data of inline production line.

BCS will upload the data to MES, OEE, SPC and so on.

BCS is widely applied to TFT/LCD industry

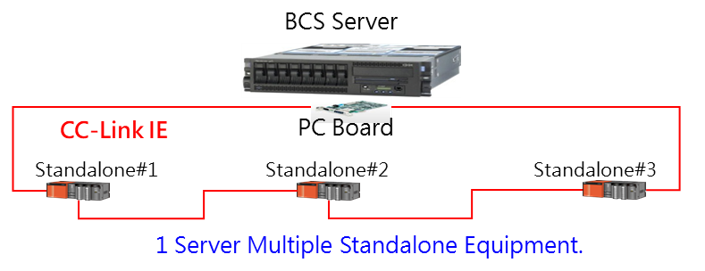

In order to save the cost, this application connects multiple standalone equipment with one CC-Link IE. As a result, the number of PC board is decreased. We can control each equipment on BCS.

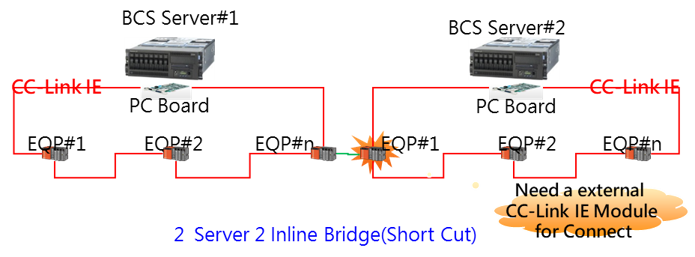

In order to save the transit time between two production time and improve the production rate, this application uses two inline bridges to create a short cut.

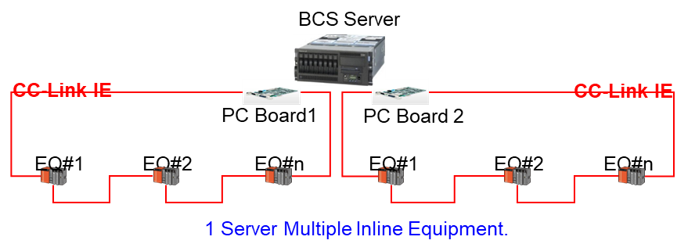

In order to share the equipment resource and manage similar production line. This application uses one BCS Server and less than three CC-link IE to connect the equipment.

| EAP | Inline EAP | BC | |

|---|---|---|---|

| 設計手法 | 單一設備資料採集 | 整線整合式規劃 | 整線整合式規劃 |

| 通訊方式 | SECS/GEM | SECS/GEM | CCLink-IE |

| 通訊連結 | 1:N | 1:N | 1:N |

| 用戶界面 | 無 | 有 | 有 |

| 線體看板 | 無 | Inline 整合式畫面 | Inline 整合式畫面 |

| 履歷查詢功能 | 無 | 有 | 有 |

| 設定方式 | 文字檔 | 視窗界面 | 視窗界面 |